What kind of company is Nippon Flavour Kogyo?

Experience Nippon Flavour Kogyo!

Visit the Nippon Flavour Kogyo company and factory on our website, and join us for a day to experience Nippon Flavour Kogyo!

Company and factory tour

Company Tour (Tokyo Development Center)

Welcome to the Tokyo Development Center.

The Tokyo Development Center has been able to create new flavours through repeated research and development.

This is the entrance to the Tokyo Development Center.

This is the entrance to the Tokyo Development Center. In the flavouring room, the flavourists formulate flavourings. In order to create new flavourings, workers here consider formulations by sniffing the flavourings of raw materials and prototypes and referencing accumulated data. One flavouring table equipped with a deodorizing function is installed for each flavourist, which prevents smells from mixing. As a result, all the flavourists can work in the same room, and the can immediately consult with senior flavourists if they have any questions.

In the flavouring room, the flavourists formulate flavourings. In order to create new flavourings, workers here consider formulations by sniffing the flavourings of raw materials and prototypes and referencing accumulated data. One flavouring table equipped with a deodorizing function is installed for each flavourist, which prevents smells from mixing. As a result, all the flavourists can work in the same room, and the can immediately consult with senior flavourists if they have any questions. In the formulation room, the raw materials are weighed and flavourings are extracted according to the formula. Because raw materials can have a strong odor, a deodorizing device is installed. This reduces the burden on the blending workers and prevents the transfer of flavourings to the finished flavouring sample.

In the formulation room, the raw materials are weighed and flavourings are extracted according to the formula. Because raw materials can have a strong odor, a deodorizing device is installed. This reduces the burden on the blending workers and prevents the transfer of flavourings to the finished flavouring sample.Also, we conduct preservation tests on flavouring samples to determine whether flavourings are stable in various environments.

In the application room, beverages and cakes are prototyped using the flavourings produced. We can make a variety of beverages, including fruit juices, carbonated drinks, and dairy beverages and the like. Also, a UHT sterilizer is installed. This makes it possible to create products under actual manufacturing conditions. In addition to that, we make all kinds of foods and beverages, such as jelly, candy, gummy, baked goods, and breads and the like, to check whether the flavourings match the products.

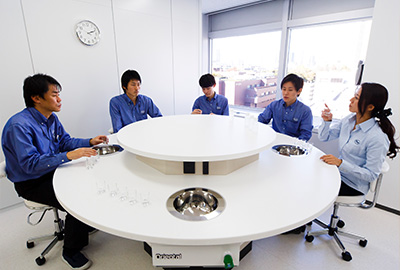

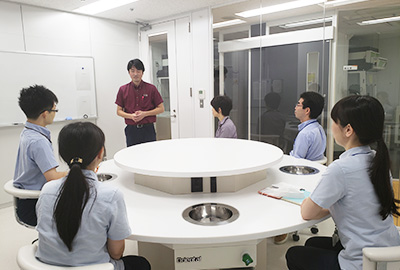

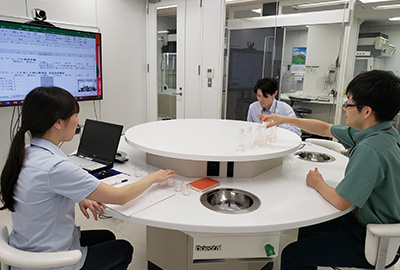

In the application room, beverages and cakes are prototyped using the flavourings produced. We can make a variety of beverages, including fruit juices, carbonated drinks, and dairy beverages and the like. Also, a UHT sterilizer is installed. This makes it possible to create products under actual manufacturing conditions. In addition to that, we make all kinds of foods and beverages, such as jelly, candy, gummy, baked goods, and breads and the like, to check whether the flavourings match the products. In the evaluation room, we evaluate food and beverages prepared in the application room. The evaluation benches installed include a sink. This makes it easy for workers easily to spit out flavourings in their mouths, and to gargle thereby improving their evaluation accuracy. Also, we are able to conduct round-table discussions and to communicate with the Sanda Factory via videoconference.

In the evaluation room, we evaluate food and beverages prepared in the application room. The evaluation benches installed include a sink. This makes it easy for workers easily to spit out flavourings in their mouths, and to gargle thereby improving their evaluation accuracy. Also, we are able to conduct round-table discussions and to communicate with the Sanda Factory via videoconference.Factory Tour (Sanda Factory)

Completed in 2006, the Sanda Factory (Hyogo Prefecture) is our flavour manufacturing factory located in Hokusetsu Sanda Technopark which is surrounded by rich, and abundant nature.

The Sanda Factory aims further to improve not only the quality of our products, but also the working environment, every day in a safe and secure working environment.

The flavours produced here may even be used in foods or beverages that are familiar to you.

Now let’s take a look at the process used leading up to the actual flavours that are produced.

Change into work clothes specialized for the workplace. Wash your hands before entering the room, and remove any foreign matter from your work clothes using an adhesive rollers, mats, and an air shower before entering the room.

Change into work clothes specialized for the workplace. Wash your hands before entering the room, and remove any foreign matter from your work clothes using an adhesive rollers, mats, and an air shower before entering the room. Collect the prescribed raw materials from the hundreds of raw materials stored and manufacture the flavour.

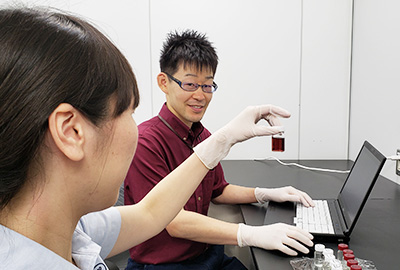

Collect the prescribed raw materials from the hundreds of raw materials stored and manufacture the flavour. Implement a physical inspection using analytical instruments such as gas chromatography or the like, and conduct a sensory test using human smell.

Implement a physical inspection using analytical instruments such as gas chromatography or the like, and conduct a sensory test using human smell.Sensory tests, which are important to verify the quality of flavourings, are carried out by trained inspectors.

Fill the shipping container with the flavour that passed the quality inspection and place it in the cardboard for shipping.

Fill the shipping container with the flavour that passed the quality inspection and place it in the cardboard for shipping.One-day Experience Joining the Company

Sales Department

The sales department is developing a commercial negotiation to propose flavourings to an existing trading manufacturer.

We work with each department to suggest the best flavouring for our customers’ requirements and issues.

Handle phone calls and email correspondence and confirm proposal materials.

Handle phone calls and email correspondence and confirm proposal materials. Collect information on flavouring proposals and new development projects.

Collect information on flavouring proposals and new development projects.

Conduct internal meetings on customer requests, prepare materials for the next day’s visits, enter daily report, and others.

Conduct internal meetings on customer requests, prepare materials for the next day’s visits, enter daily report, and others.

Development Department

The Development Department is where we develop flavourings. We create flavourings by formulating raw materials to meet the requirements and to finish a flavouring.

The work of flavouring development is interesting in that the personality of the person in charge will come through in the selection of ingredients and the like.

We design flavourings by smelling the scents of prototypes and the ingredients.

We design flavourings by smelling the scents of prototypes and the ingredients. We add flavourings to items that are similar to the final product (beverages, jellies, and the like) to taste for evaluation.

We add flavourings to items that are similar to the final product (beverages, jellies, and the like) to taste for evaluation. We actually formulate the flavouring. This is a very delicate work because it requires us to be accurate in 0.01g units.

We actually formulate the flavouring. This is a very delicate work because it requires us to be accurate in 0.01g units. We check because flavourings may change color and flavour over time.

We check because flavourings may change color and flavour over time. Knowledge and experience are questioned because there is no fixed method for determining the composition of a flavouring.

Knowledge and experience are questioned because there is no fixed method for determining the composition of a flavouring.

We value connecting with other workers who are involved in the development of flavourings in order to satisfy our customers.

We value connecting with other workers who are involved in the development of flavourings in order to satisfy our customers.Manufacturing Department

It is the job of the Manufacturing Department job to formulate and to process according to the prescription for the scent that will satisfy our customers’ requirements.

For example, the process for a liquid citrus flavourings used in a cool drinking water is to manufacture with the processes of extraction > formulation > constant temperature filtration > inspection > filling and packaging.

The constant temperature filtration process is essential to ensure that the formulated citrus flavourings have clarity. The responsibilities are heavy, but the job is very rewarding.

We take on our work by imagining in advance that we can finish at a predetermined standard time.

We take on our work by imagining in advance that we can finish at a predetermined standard time. There are no major differences in work depending on the type of product, but because the properties of the product differ depending on the raw materials used, we must adjust the conditions such as filtration filter and filtration rate according to the situation. The filtration situation can also vary according to the extraction conditions of the previous process. Therefore, we take data on the filtration status and examine the filtration conditions daily to ensure we attain efficient filtration.

There are no major differences in work depending on the type of product, but because the properties of the product differ depending on the raw materials used, we must adjust the conditions such as filtration filter and filtration rate according to the situation. The filtration situation can also vary according to the extraction conditions of the previous process. Therefore, we take data on the filtration status and examine the filtration conditions daily to ensure we attain efficient filtration. Since the constant temperature filtration work processes multiple lines simultaneously, the timing of the end of filtration may be affected, making it difficult to assemble the operation order

Since the constant temperature filtration work processes multiple lines simultaneously, the timing of the end of filtration may be affected, making it difficult to assemble the operation order

We also implement thorough hygiene management for safety and security.

We also implement thorough hygiene management for safety and security. We try to consult with each other if we have any questions even concerning trivial matters without trying to solve them by ourselves.

We try to consult with each other if we have any questions even concerning trivial matters without trying to solve them by ourselves.

We are committed to producing flavourings every day, without failing to check our quality and to work safely.

We are committed to producing flavourings every day, without failing to check our quality and to work safely.